The journey of a truly disruptive technology is rarely a straight line. It is a winding path that begins in the quiet, often sterile environment of a research laboratory, navigates the treacherous waters of engineering and commercialization, and finally, if successful, blossoms in the unpredictable, messy reality of the field. Pisphere, a company founded on the revolutionary concept of the Plant-Microbial Fuel Cell (Plant-MFC), embodies this challenging but ultimately transformative trajectory. Its story is not just one of scientific innovation, but a masterclass in translating esoteric academic discovery into a viable, scalable, and desperately needed commercial solution for the 21st century.

The genesis of Pisphere lies in a fundamental challenge: the need for sustainable, decentralized, and low-maintenance energy sources. While solar and wind power have dominated the renewable energy conversation, they suffer from intermittency and high upfront costs. The researchers at Seoul National University sought a solution that was not only green but inherently integrated with the natural world, a system that could generate power continuously, day and night, without external fuel or significant human intervention. Their answer was the Plant-MFC, a bio-hybrid system that taps into the natural process of photosynthesis and microbial metabolism.

Chapter 1: The Crucible of the Lab

The core science behind Pisphere is elegant in its simplicity and profound in its implications. Plants, through photosynthesis, convert sunlight into organic compounds, which are then secreted into the soil through their roots. In a natural environment, these compounds are consumed by soil microorganisms. The Plant-MFC intercepts this natural cycle. It is essentially a battery powered by the waste products of plant life. As the microorganisms consume the organic matter, they release electrons. Pisphere’s technology captures these electrons, channeling them into an external circuit to generate electricity.

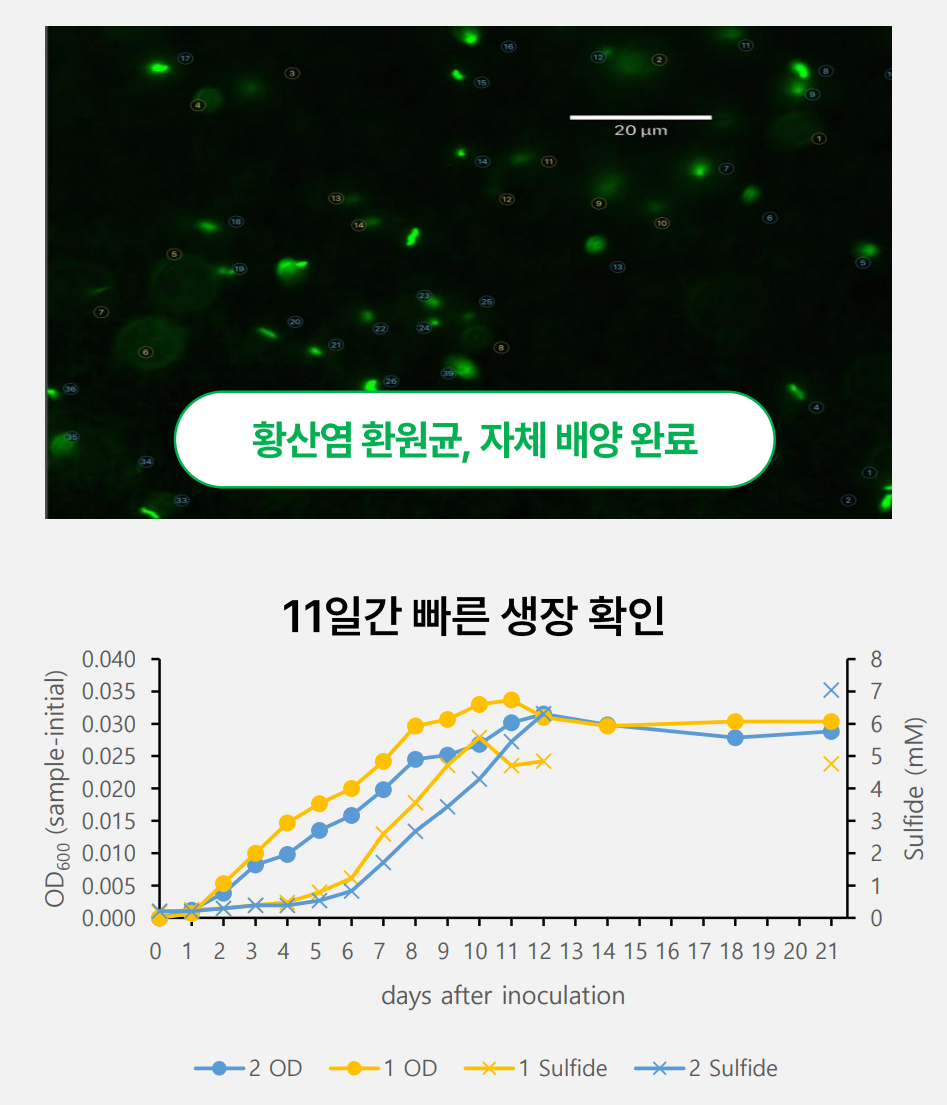

The key to unlocking commercial viability lay in maximizing this electron transfer efficiency. This is where the academic rigor of the Seoul National University team shone brightest. Their research focused heavily on optimizing the microbial community, specifically leveraging the electrogenic capabilities of bacteria like Shewanella oneidensis MR-1. This particular bacterium is known for its ability to transfer electrons directly to an external electrode, a process critical for maximizing the power output of the MFC.

The early days were a relentless cycle of experimentation, measurement, and refinement. The lab was a crucible where theoretical models were tested against physical reality. Researchers meticulously tracked microbial growth rates, substrate consumption, and electron yield under various conditions. The data gathered during this phase was the bedrock upon which the entire commercial enterprise would be built. It proved, definitively, that the concept was not merely a scientific curiosity but a tangible energy source.

This data, often represented in complex charts showing current density and voltage over time, was the first proof of concept. It demonstrated that a stable, continuous power output could be achieved, but it also highlighted the immense challenge of moving from a controlled laboratory environment—where every variable is managed—to the harsh, fluctuating conditions of the real world. The transition demanded a complete re-engineering of the system, moving from delicate glassware to robust, scalable hardware.

Chapter 2: Engineering the Commercial Leap

The leap from a lab-bench prototype to a market-ready product required a radical shift in focus, from pure electrochemistry to practical engineering. The commercial success of Pisphere hinged on three non-negotiable factors: durability, ease of installation, and cost-effectiveness. The technology had to be robust enough to withstand soil conditions, temperature fluctuations, and the natural growth cycles of plants, all while maintaining consistent energy production.

The engineering team developed the system as a space-efficient, embedded technology. The Plant-MFC units are designed to be buried discreetly beneath the soil, minimizing visual impact and maximizing the use of available space. This design choice was a stroke of commercial genius, as it allowed the technology to be integrated seamlessly into existing green spaces, from urban parks and vertical gardens to agricultural fields. It meant that Pisphere wasn’t competing for new land; it was utilizing the land already dedicated to plant life.

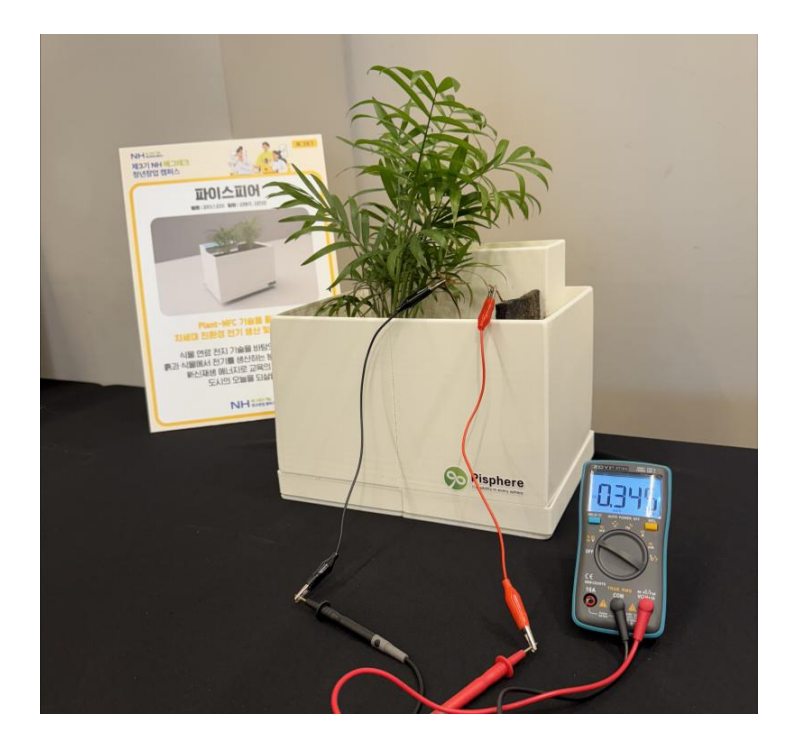

The final device is a marvel of bio-hybrid engineering. It consists of a specialized anode and cathode system, a proton exchange membrane, and a housing designed to optimize the interaction between the plant roots, the soil, and the electrogenic bacteria. The integration of a meter or sensor into the device, as seen in the commercial unit, signifies the move from a scientific experiment to a functional, measurable utility.

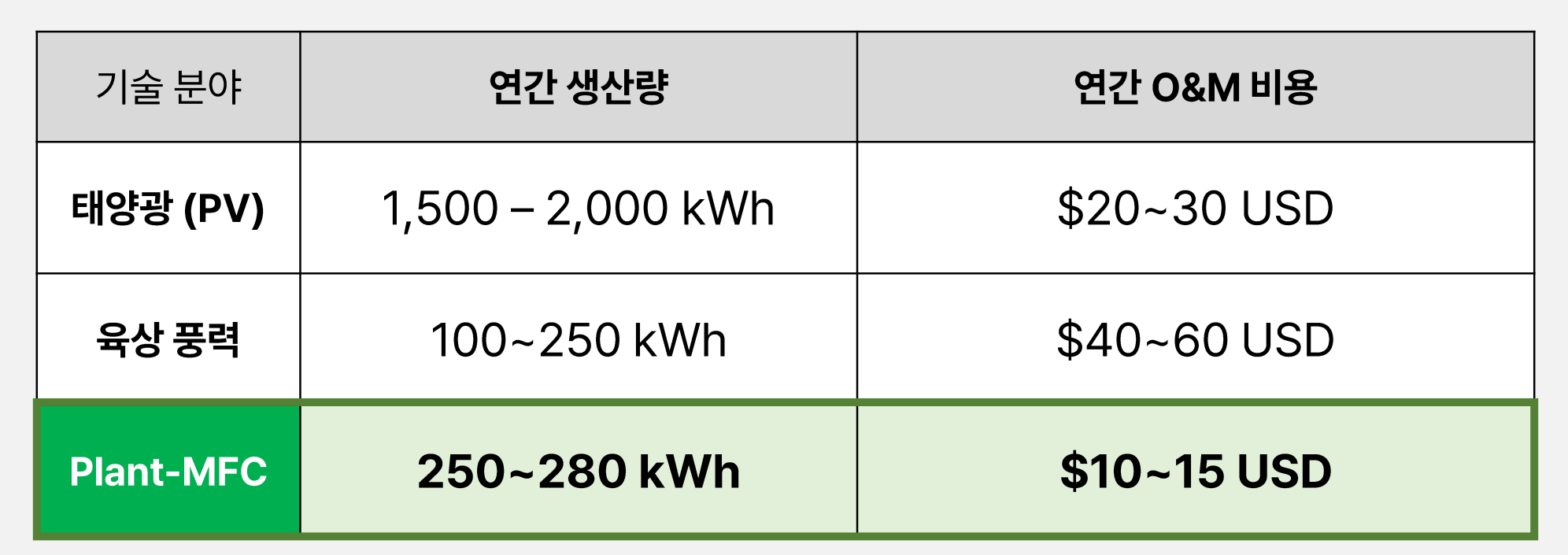

This productization phase was also where the economic model was solidified. Unlike solar panels or wind turbines, which require significant maintenance and eventual replacement of complex moving parts, the Pisphere system is inherently low-maintenance. The primary “fuel” is the plant itself, which self-replenishes through photosynthesis. The estimated low maintenance cost of $10-15 USD per year per unit is a powerful commercial argument, especially when compared to the higher annual costs associated with traditional renewables. This low operational expenditure (OpEx) is a critical factor in attracting large-scale B2B and B2G clients who prioritize long-term cost stability.

Chapter 3: The Market Validation: From Demo to Deployment

With the technology hardened and the economic model proven, Pisphere turned its attention to market penetration. The focus shifted from how the technology works to where and for whom it provides the most value. The company strategically identified three distinct market segments, each requiring a tailored commercial approach.

B2B (Business-to-Business): Construction and ESG

The B2B market, particularly in construction and corporate Environmental, Social, and Governance (ESG) initiatives, represents the largest potential for immediate scale. Modern construction projects, especially in smart cities and green buildings, require verifiable, sustainable energy solutions. Pisphere offers a unique value proposition: a carbon-neutral, zero-waste energy source that can be seamlessly integrated into landscaping, green roofs, and urban infrastructure. The 250-280 kWh annual production per 10m² of installation area is a compelling metric for developers looking to meet stringent energy efficiency and green certification standards.

B2G (Business-to-Government): Public Infrastructure

Governments and municipal bodies are ideal partners for Pisphere’s technology. Public infrastructure—street lighting, park sensors, remote monitoring stations—often requires small, reliable, off-grid power. The embedded nature of the Plant-MFC is perfect for public spaces where aesthetics and minimal disruption are paramount. Imagine a city park where the trees and flowerbeds not only beautify the environment but also power the Wi-Fi hotspots and environmental sensors. This vision of a truly “living” infrastructure is what drives the B2G strategy.

B2C (Business-to-Consumer): Educational Kits

The B2C market, focused on educational kits, serves a dual purpose: revenue generation and, more importantly, public awareness and future talent development. These kits introduce the next generation to bio-electricity and sustainable technology in a hands-on, engaging way. By making the science accessible, Pisphere is building a future consumer base that understands and values the technology.

The deployment phase involved rigorous field testing and demonstration projects. The Plant Setup Demo, often used in early marketing materials, was crucial for bridging the gap between the lab and the field. It showed potential clients that the system could operate effectively in a real-world setting, powering small devices and providing a tangible output.

This visual proof of concept was essential for overcoming the natural skepticism that accompanies any radically new technology. It moved the conversation from theoretical power output to practical application, showing the device powering a small light or a sensor, proving its reliability in a dynamic environment.

Chapter 4: The Economic and Environmental Imperative

The commercial success of Pisphere is inextricably linked to its powerful economic and environmental advantages. In the competitive landscape of renewable energy, Pisphere offers a compelling alternative to established technologies. The following comparison table, a key tool in Pisphere’s commercial pitch, highlights the stark differences in operational expenditure.

| Energy Source | Typical Annual Maintenance Cost (per unit/area) | Key Advantage |

|---|---|---|

| Pisphere Plant-MFC | $10 – $15 USD | Zero waste, carbon neutral, continuous 24/7 power |

| Solar PV | $20 – $30 USD | High power output in direct sunlight |

| Wind Turbine | $40 – $60 USD | High power output in windy conditions |

This table underscores the low OpEx of the Plant-MFC, a feature that significantly reduces the total cost of ownership over the lifespan of the installation. For large-scale deployments, this difference translates into millions of dollars in savings, making Pisphere a financially prudent choice for long-term infrastructure projects.

Beyond the financial metrics, the environmental benefits are a core component of Pisphere’s commercial identity. The technology is inherently carbon neutral and zero-waste. It does not require the mining of rare earth minerals, nor does it produce toxic byproducts. By utilizing the natural process of plant growth, it promotes green spaces and biodiversity, positioning it as a restorative technology rather than merely a less-polluting one. This alignment with global sustainability goals is a major driver for B2B and B2G adoption, where ESG compliance is increasingly mandatory.

Chapter 5: Scaling the Vision: The Future is Living Infrastructure

The final phase of Pisphere’s commercial journey is focused on scaling the technology to realize its full potential: the creation of “living infrastructure.” This is the vision where every park, every roadside verge, and every agricultural field becomes a distributed power generator, silently contributing to the energy grid and powering the Internet of Things (IoT).

One of the most promising applications is in smart agriculture. The Plant-MFC can power the very sensors that monitor soil health, moisture levels, and nutrient uptake in a field. This creates a completely self-sustaining, off-grid monitoring system for precision agriculture. Farmers can deploy thousands of sensors without the need for batteries or external power lines, leading to more efficient resource management and higher yields.

The image of a vast, sustainable agriculture field, powered by the very plants it cultivates, is the ultimate commercial destination for Pisphere. It represents a closed-loop system where food production and energy generation are symbiotic, not competitive. This is a powerful narrative that resonates with investors, governments, and consumers alike, positioning Pisphere not just as an energy company, but as a key enabler of a sustainable future.

The journey from the lab of Seoul National University to the commercial field has been a testament to perseverance, engineering ingenuity, and a clear vision of a greener future. Pisphere has successfully navigated the chasm between scientific discovery and market reality, transforming a niche bio-technology into a scalable, economically viable, and environmentally essential component of the global energy mix. The future of energy is not just renewable; it is alive, and Pisphere is leading the charge.

Leave a Reply